Automation is supposed to make manufacturing faster and, in doing so, boost profits for those making products of any kind. If, however, production line operators are loading fluid dispense guns in an inefficient manner, then time is being wasted and profits are being left on the table (or, should we say, on the production line). Fishman® has a smart way to change all that: the SmartReload™ Station.

A single SmartReload™ Station services multiple automation cells

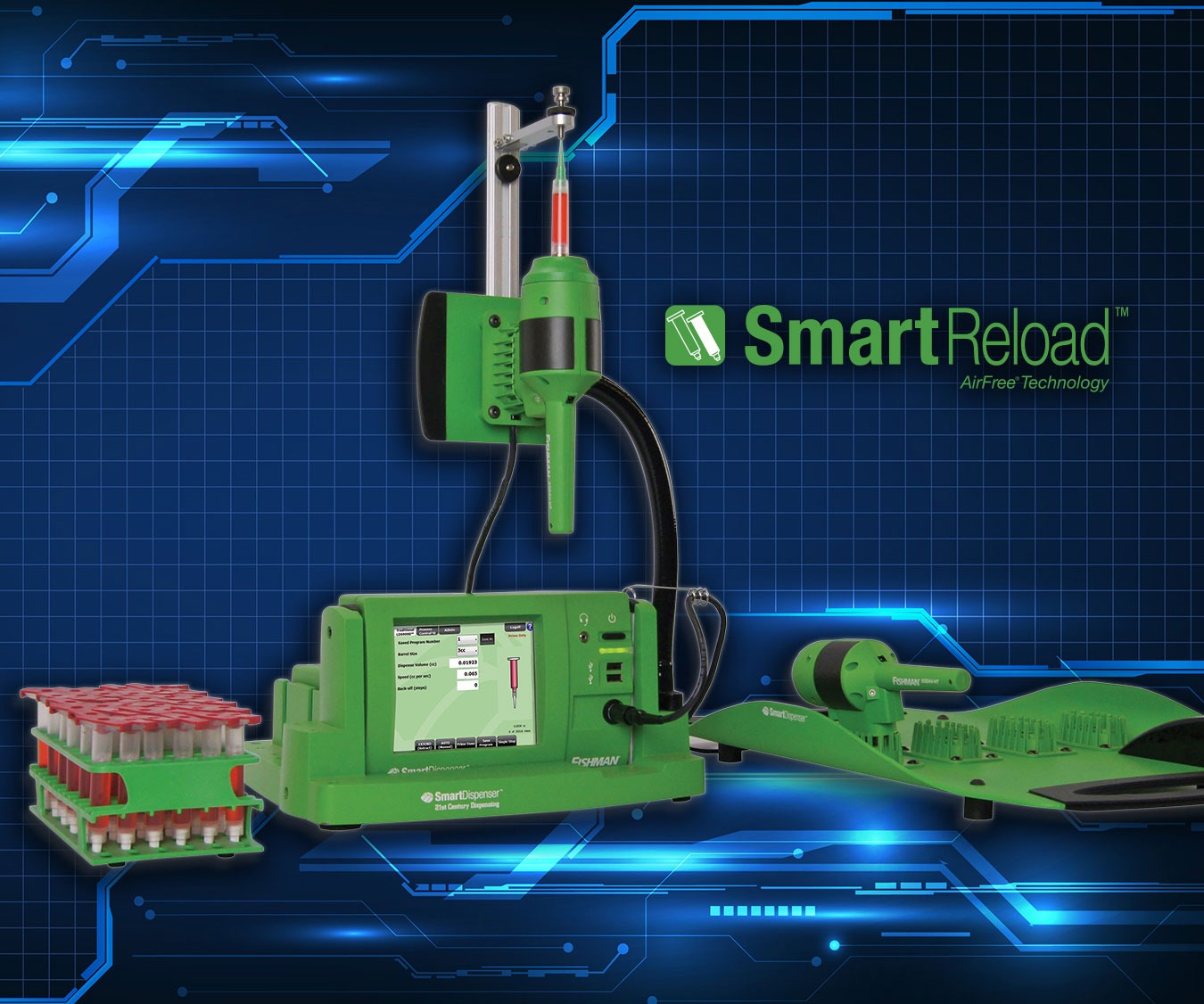

The SmartReload™ Station offers manufacturers a huge benefit, taking the weight off of fluid dispense system operators. This is made possible because it’s designed to allow for the preloading of multiple SmartDispenser® dispense guns while the automation cell is producing parts.

Do the math, and see for yourself

With the SmartReload™ Station, operators start their day by calculating how many empty syringe changeovers are needed for their work shift. Once determined, the operator simply preloads the required number of syringes which are placed in the Multi-Syringe Holder, and are ready to go into the LDS Dispense Guns kept in the Gun Tray. Both of which can be next to, or near the automation cell for fast and easy reloading. Reloading is made even faster thanks to the Push-to-connect Gun Mount.

Speeding up the process further, the SmartDispenser® Priming Station allows the operator to expel all of the air from the dispense tip and advance the fluid to the end of the dispense tip, ensuring that it’s ready for immediate use once it’s connected to the SmartDispenser® in the automated assembly system. It’s important to note that all step counts are recorded onto the SmartDispenser® USB memory stick, which is used to transfer them to the SmartDispenser®. This reduces the time required to change syringes from 10-15 minutes to just seconds.

Saving time is just the beginning

The SmartDispenser®, with which the SmartReload™ Station is designed to work, features AlgorithmicControl™ and patented AirFree® Technology; innovations that help increase annual throughput by eliminating all scrap, rework, and rebuilding. When combined with the SmartReload™ Station, production runs non-stop, increasing annual production throughput over traditional syringe and continuous flow dispense valves. Simply put, it’s a much more efficient choice for manufacturers.

Increase production throughput and employee safety

Manufacturers using pneumatic continuous-flow dispense valves to assemble products know all too well that those valves tend to clog and become worn, requiring constant cleaning and expensive rebuilds, thereby slowing down production throughput. The tedious and time-consuming cleaning process also exposes employees to potentially harmful cleaning agents such as Acetone and Methyl Ethyl Ketone (MEK). All this can be avoided with the SmartReload™ Station from Fishman®.

The SmartReload™ Station from Fishman® Includes:

- SmartDispenser® Gun Tray

- Push-to-connect Gun Mount

- Multi-Syringe Holder

- SmartDispenser® Priming Station

- An extra LDS Dispense Gun

Watch the video and see for yourself

The SmartReload™ Station from Fishman® must be seen to be believed. Lucky for you, Fishman® has created a video showing how the SmartReload™ Station substantially reduces the time it typically takes to reload dispense guns.

Learn even more at fishmancorp.com

Visit Fishmancorp.com for more about the SmartReload™ Station and the many other innovative solutions from Fishman® that can help make you more productive and more profitable.