If you’re not attending, you can also connect by reading this blog

Connecting with the best has never been easier

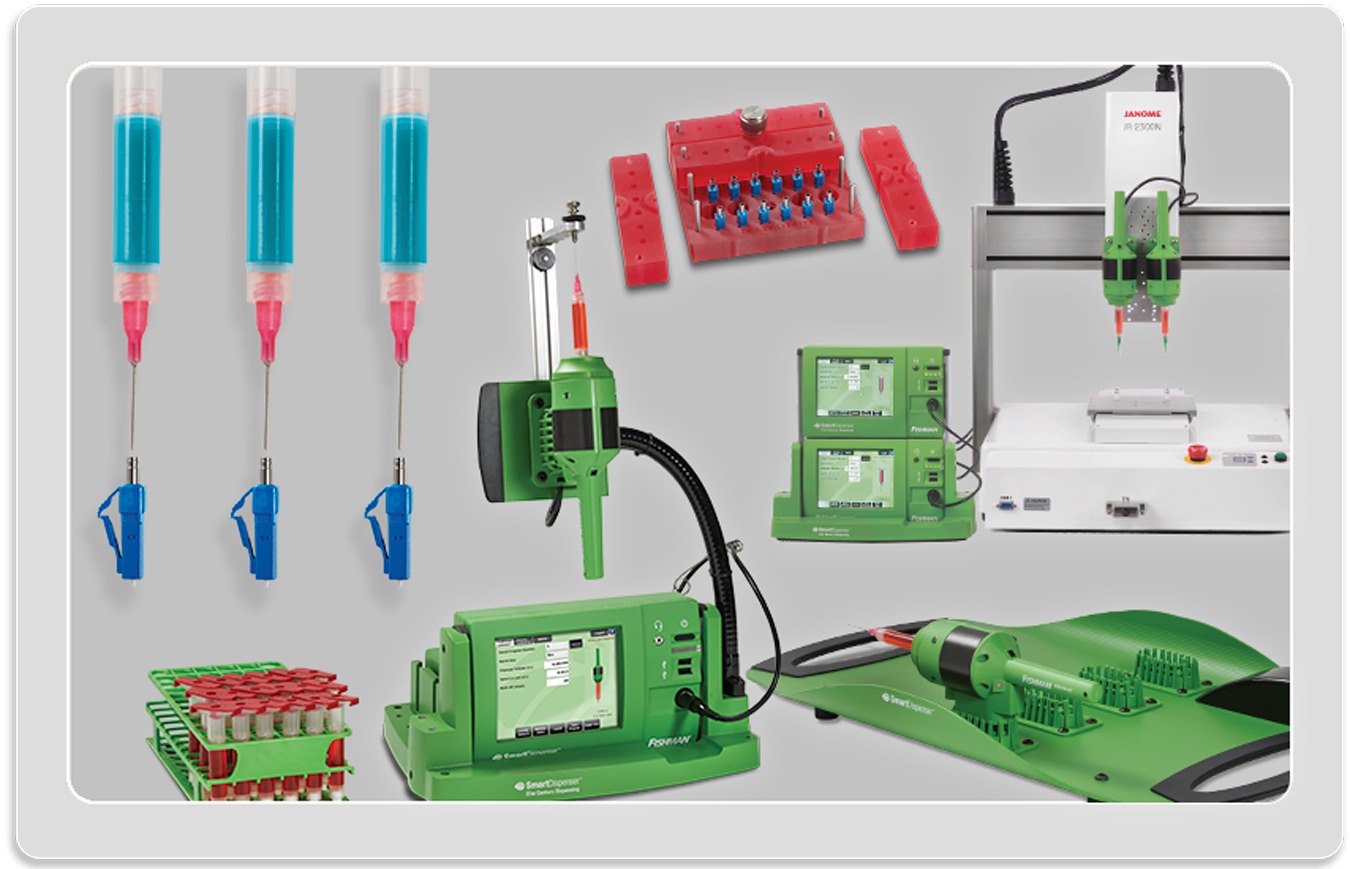

The SmartDispenser® from Fishman® Corporation can be found on the production lines of a wide range of industries. That is not so surprising since the SmartDispenser® is known for delivering the highest level of precision and control which greatly improves the assembly process, resulting in increased productivity, yields and profits.

One industry group that has come to rely on the capabilities of the SmartDispenser® includes the providers of LC, SC and MT fiber optic connector assemblies. To bolster their trust in us, we created a quick, easy and affordable way for them to find the right fluid adhesive systems to match their exact production needs—it is the Fiber Optic Connector Assembly Program (FOCAP).

It is clear to see why many tip their cap to FOCAP

By offering three distinct solutions, FOCAP appreciably eases the selection and ordering process. This reduces manufacturing downtime which leads to increased throughput and profits. The three Program Choices are designed to accommodate companies with annual production yields, ranging from low to mid to high.

Program Choice One features the SmartDispenser® MINI™ with AlgorithmicControl.™ It is ideal for dispensing epoxies for bonding glass fiber to ceramic ferrules. It also ensures each ferrule is filled without overflow or air gaps. All this delivers a degree of repeatability that is crucial when performing assembly work of this type.

Program Choice One features the SmartDispenser® MINI™ with AlgorithmicControl.™ It is ideal for dispensing epoxies for bonding glass fiber to ceramic ferrules. It also ensures each ferrule is filled without overflow or air gaps. All this delivers a degree of repeatability that is crucial when performing assembly work of this type.

Program Choice Two features the SmartDispenser® with AirFree® Technology. It not only delivers AlgorithmicControl,™ but with AirFree® Technology, it offers providers of fiber optic connector assemblies with a host of other important benefits not attainable with any other fluid dispense system.

Program Choice Two features the SmartDispenser® with AirFree® Technology. It not only delivers AlgorithmicControl,™ but with AirFree® Technology, it offers providers of fiber optic connector assemblies with a host of other important benefits not attainable with any other fluid dispense system.

Program Choice Three is there when production ramps up. It combines AlgorithmicControl™ with the LC/MT/SC Genius™ Precision ConnectorMount,™ the High Precision Benchtop Robot, the SmartReload™ Station and the Fiber Optic Connector SmartApp.™ With this fully equipped solution companies have everything they need to ensure each fiber optic connector is filled precisely, cycle after cycle.

Program Choice Three is there when production ramps up. It combines AlgorithmicControl™ with the LC/MT/SC Genius™ Precision ConnectorMount,™ the High Precision Benchtop Robot, the SmartReload™ Station and the Fiber Optic Connector SmartApp.™ With this fully equipped solution companies have everything they need to ensure each fiber optic connector is filled precisely, cycle after cycle.

FOCAP lets customers move up when the time comes

There is a lot to like with FOCAP, but one benefit that stands out is the fact that each Program Choice is upgradable to the next option. Here is how it works—when customers choose the SmartDispenser® MINI™ they are told it comes with a buy-back program that makes it both easy and affordable to upgrade to the SmartDispenser® Benchtop System. As production needs increase, customers with the Benchtop System know that it can be readily integrated into the SmartAutomation™ Platform.

What all this means is that with FOCAP, the original investment customers make is never lost, because as production grows, so does the SmartDispenser;® the most flexible fluid dispensing system available today.

Innovative technologies that further strengthen connections

The technologies behind the SmartDispenser® deliver a host of advantages that are not possible with any other products on the market today. These benefits include the following:

Providing blind fill capabilities that hit the mark

- Volume is entered numerically in cubic centimeters

- The SmartDispenser® dispenses that volume ±2-5%

- Guarantees connectors are filled each time

Alleviating the effects of changing epoxy viscosities

- The linear mechanical drive system of the SmartDispenser® uses algorithms

- This mitigates the impact of changing viscosity on the fluid dispense volume

Assuring standardization of each system in use

- Dispense program is numerical

- Can be duplicated on each menu of each system

- Can be documented in a work instruction

- Every operator workstation performs exactly the same regardless of global location

- Validation results from new product development can be duplicated when installed in production

Eliminating the possibility of air entrapment

- Precise control of the dispense tip while filling allows for precise epoxy placement in the connector eliminating the potential for air pockets

- Process control over dispensing speed also reduces turbulence which can cause air pockets and bubbles

- Using the DualDrive™ gun with side by side cartridges eliminates unreliable by-eye dispensing when assembling MT Connectors

For more information about the Fiber Optic Connector Assembly Program (FOCAP) or on the many other innovative solutions and programs offered by Fishman® Corporation, please visit fishmancorp.com or if you’d like, call and ask to speak with a sales representative at 800-433-2115.