It’s only natural for Fishman® customers to be excited after making the decision to purchase the SmartDispenser®. They’re eager to put it on the production line, and start reaping the rewards that come with AlgorithmicControl™ and patented AirFree® Technology. But before they unleash the potential of the SmartDispenser®, Fishman® asks them to take a step back and perform a capabilities test. Doing so provides customers with a Master Capability Report that confirms why they bought the SmartDispenser® in the first place.

The SmartDispenser® is engineered to pass the test with flying colors

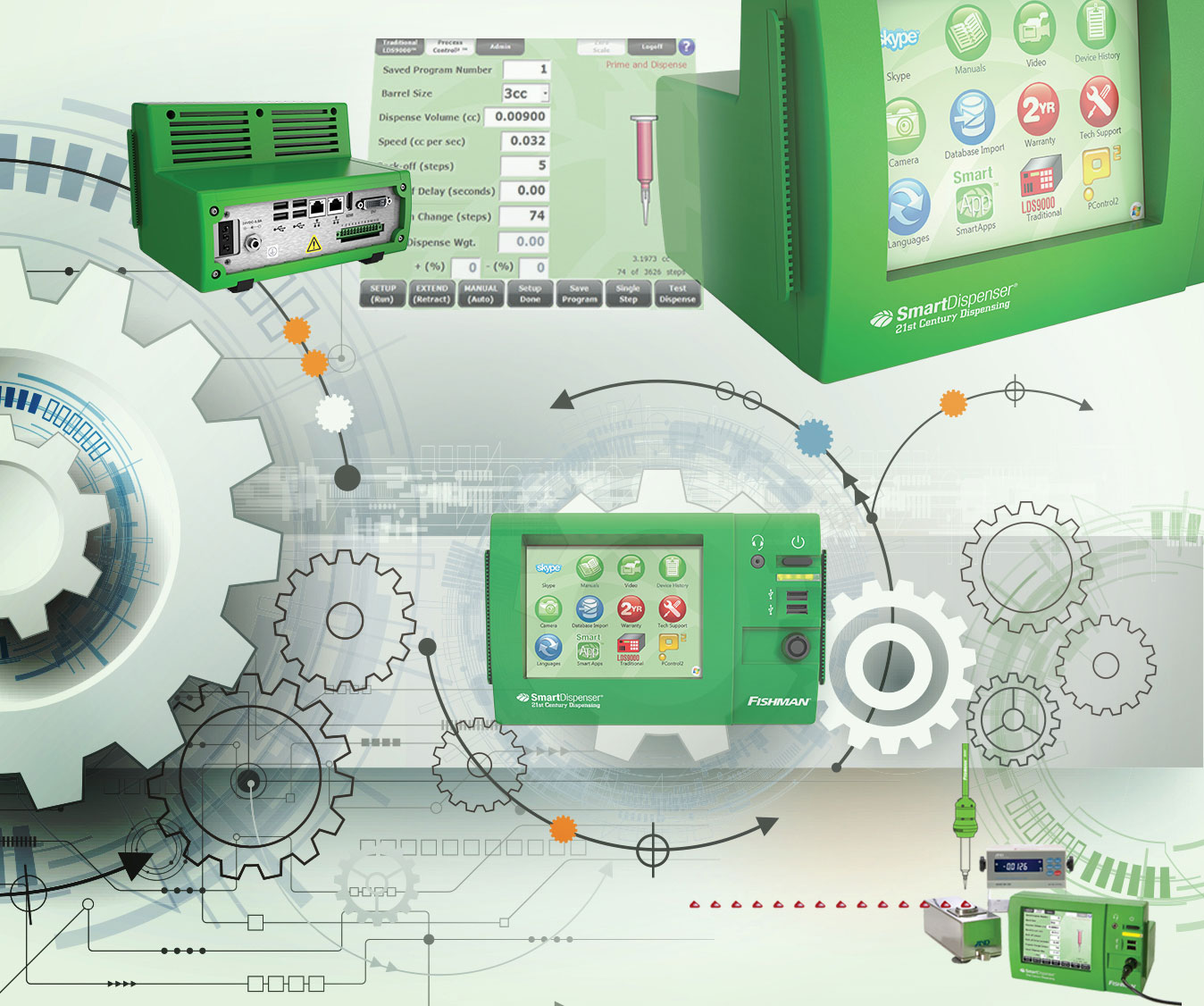

Performing a capabilities test is pretty straightforward, and only requires the dispensing of a full syringe reservoir onto the weighing sensor. Fishman® designs each SmartDispenser® to communicate with the A&D Company AD4212B Analytical Weighing Sensor. To begin the test, all the SmartDispenser® administrator has to do is activate the weighing sensor option in the administration section of the SmartDispenser®.

Once initiated, the weighing sensor automatically records all weight data which goes into a file on the SmartDispenser®’s hard drive. The data can be downloaded via a USB memory stick or local network and imported into Excel to calculate the mean and standard deviation. The mean is the customer’s target weight and the standard deviation, which is calculated into a percentage, is their +/- tolerance. The Master Capability Report generated from the test data is the customer’s statistical measurement of a process’s ability to produce parts within specified limits on a consistent basis.

It’s important to take capabilities tests regularly

Fishman® strongly recommends that customers set up a Calibration Station, complete with an Analytical Weighing Sensor, in their Quality Control Department. Having such a station allows customers to easily and quickly pull a SmartDispenser® from the production line, and perform a capabilities test on it once or twice a year. Using the data from the Master Capability Report as a benchmark, input the target weight and tolerance into the SmartDispenser® GUI. After each dispense, the SmartDispenser® will compare the actual weight dispensed to +/- tolerance and, if out of tolerance, a warning message will appear on screen and will need to be cleared before the SmartDispenser® returns to operation.

All weights and weight stoppage from the new tests are automatically recorded to an Excel CSV file for post calibration analysis. If the current data matches the test data on the Master Capability Report, customers are assured the SmartDispenser® is performing within specification. If there’s a difference in the data comparison, all the customer needs to do is contact Fishman® Corporation’s Technical Service, and a professional will help get the SmartDispenser® back into calibration.