Technicians no longer need to live with the uncertainties and shortcomings of pneumatics or deal with the production delays due to the need to calculate and recalculate settings, material waste, and inconsistent performance that happen as a result. Fluid dispensing has gone AirFree®.

Key performance features and capabilities of AirFree® fluid dispensing include:

Operation without air supply

Fluid dispensers traditionally relied on pneumatics to “push” the material out of the barrel reservoir which caused problems such as inconsistent dots due to variations in air pressure and changes in viscosity due to build-up. Fishman Corporation revolutionized fluid dispensing with the SmartDispenser® fluid dispensing system that utilizes AirFree® technology to eliminate the variations associated with air pressure dispensing. With the SmartDispenser®, exact amounts of adhesive can be dispensed without variations in applied pressure, without problems with moisture and changing viscosity, and without degradation in repeatability as the amount of material is reduced within the syringe during dispensing.

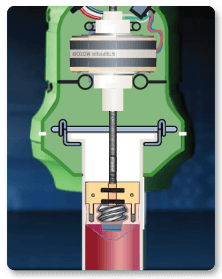

Linear actuator-driven mechanical lead screw

The linear actuator-driven mechanical lead screw lowers a piston on command from a microprocessor control unit to push the material through the syringe and out the tip. An interference fit between the plunger and the syringe ensures against leakage of material and loss of pressure.

Screw that travels along its axis

This is the key to the smooth operation and precision movement of the fluid dispenser, which separates the Fishman AirFree® fluid dispensing technology from other dispensers on the market.

Mechanical action of the lead screw

With the SmartDispenser®, control is achieved with the linear drive system and not by the size of the needle. The proper needle size can be used for the material and the application so the adhesive is in a relaxed state and dispenses smoothly. Materials with fillers remain homogenous. Tunneling does not occur, and without air, no infusion of moisture or other contaminants is possible. Precise dispensing is achieved, even with changing viscosity.

Evenly applied force

When an adhesive is compressed between an auger thread and the housing as it moves through the pump, changes to the properties of the material are possible. Fishman AirFree® fluid dispensing technology ensures that force is applied evenly to the material across the face of the plunger and dispensing occurs without crushing the adhesive.

Intelligent microprocessor

Companion to the AirFree® fluid dispenser is an intelligent microprocessor that provides precise control over the volume output, based on the prescribed dispense rate and the known inside diameter of the syringe being used.