Assembly Fluid Application Program (AFAP)

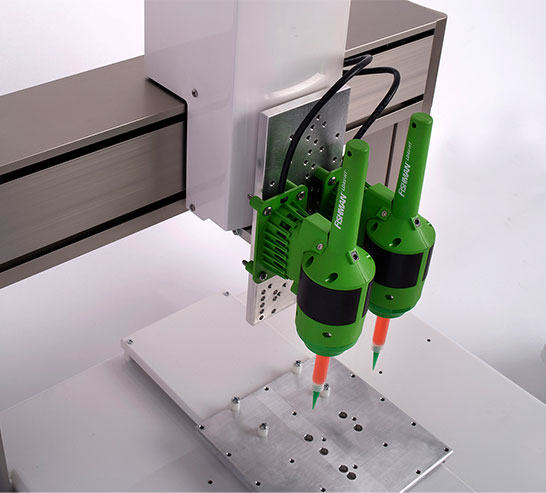

Thanks to the AlgorithmicControl™ feature of AirFree® Technology, algorithms controlling the automation system axes can now be coordinated with algorithms controlling the LinearDrive™ System (LDS) of the SmartDispenser.® This provides unprecedented control of fluid deposits and fluid beading, achieving flawless automation. This major innovation and the advantages gained from having it are only available from Fishman® Corporation.

The SmartDispenser® features AirFree® Technology. It not only delivers AlgorithmicControl,™ but it also provides manufacturers with a host of other benefits not possible with compressed air systems. AirFree® Technology—

- Provides automatic production data reporting that management can review and use

- Eliminates human error by reducing operator interaction by utilizing tools such as barcode scanning

- Has available an on-board database that lets the SmartDispenser® make decisions like verifying the assembly fluid, automatically loading a program and locking the system when wrong operator choices are made

- Allows the SmartDispenser® to network with servers or MES systems for command, control and reporting functions

As new versions of AirFree® Technology are released, the SmartDispenser® can be safely updated with the latest innovations via a local USB memory stick. Fishman® Corporation also offers SmartApps™ that let manufacturers customize their SmartDispenser® to enhance their specific process.

All automation systems are built with multiple axes. Algorithms are used to coordinate these axes. With AirFree® Technology’s AlgorithmicControl™ feature, manufacturers can at last replace their compressed air systems, and bring the power and precision of algorithms to the fluid dispensing drive system. And, the only system on the market today with the capabilities to do this is the LinearDrive™ System (LDS) of the SmartDispenser.®

Optional 19 Inch Din Rail Mount

AFAP Program Choice 3 is also available with an optional 19 Inch Din Rail Mount. Its reduced size makes it easy to install, and helps to lower the cost of putting a fully automated SmartDispenser® Benchtop System to work on a production line.