Tips

Genius® PosiLok™

Dispensing Tips

How dispensing tip selection differs from air to valve systems?

![]()

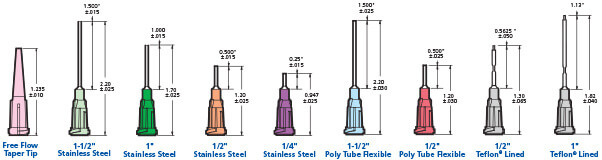

Systems using air as a drive system experience out of control swings in repeatability from one fluid dispense to the next. As a countermeasure, smaller gauge dispenser tips such as 25G, 27G, and 32G are often used as flow controls to try to mange the inconsistency. When the root cause of the problem -air pressure- is replaced by the AirFree® Linear Drive System (LDS) the flow control is no longer needed. In fact, because the LDS is positively displacing fluids the exact opposite should happen. Open up the flow by going to the largest gauge possible such as a 14G, 16G or 18G dispense tip and reduce the dispense cycle time. Also, increasing length of the dispense tip from ¼” to ½” to 1” more than doubles pressure in the syringe for each increase. Using the shortest tip possible will further reduce your cycle time. Lastly, using a cone shaped FreeFlow™ tip removes restriction points common in a Stainless Steel dispense tip. A switch to this dispensing tip will also reduce cycle time.

To recap:

- Largest gauge possible

- Cone shaped FreeFlow™ tip is best

- If a Stainless Steel dispense tip is needed use the shortest length possible (1/4” length).

- For more detailed descriptions of specific dispense tips and applications please visit our FLICKR site.