Instead of using pneumatics, the SmartDispenser® Linear Drive System (LDS) employs a linear actuator that controls the rotation of a lead screw. This control over the lead screw then controls the linear movement of the piston in the syringe. The Linear Drive System differs from all other types of pumps in both design and functionality because it is a true positive displacement pump. Each increment of mechanical actuation (even during ramp up and ramp down) results in a specific volume of fluid dispense every time, despite the viscosity of the material.

The LDS is a system that is made up of two parts: the dispensing gun and the control unit. The dispensing gun is the working tool. It can be held in the hand or mounted to a frame. The control unit is the “brains” of the operation. It automatically ensures the precise amount of output from the gun each and every time it is triggered.

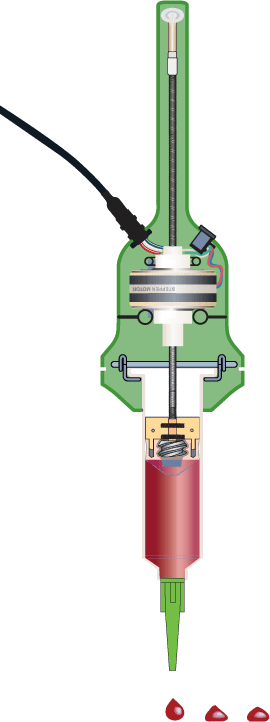

Construction of the Patented AirFree® Linear Drive System is as follows:

A precision stepper motor housed in a precision molded electronic enclosure. A stainless steel plate with stainless steel interlocking tabs connect the syringe retaining ring to the gun housing. A precision machined lead screw runs through the motor and connects to the syringe piston via a luer lock thread. A nut located in the center of the motor spins in response to charged magnetic poles holding the screw still, thus moving in a linear motion. A clam shell piston stabilizer clamps around the luer lock thread, nestling into and around the piston and preventing it from cocking left or right while under pressure. This positive lock connection assures no flexing occurs under pressure. Flexing leads to pressure loss and pressure loss destroys repeatability between one fluid deposit to the next.

Operation of the Patented AirFree® Linear Drive System is as follows:

The LDS drive system, driven electrically, ramps to full speed protecting fluid formulations and their bonding properties. An intuitive, volume-based menu system controls the firmware driving the Linear Drive System . A universal power supply converts 110v or 220v into the needed current automatically. Combine the stable voltage menu system with the Linear Drive System and one dispense program will perform exactly the same on a second SmartDispenser®. Depending on the fluids formulation and syringe filling process dispense repeatability between +/-5% and +/-2% is possible.

The SmartDispenser® Linear Drive System (LDS) replicates the fluid dispense process from one SmartDispenser® to another SmartDispenser® to ensure repeatability and less waste.