As a former competitive swimmer, I spent a lot of time in pools. When we weren’t swimming laps, we’d try to imitate what we saw the Olympic synchronized swimming ladies doing. None of us were very successful. The upcoming Olympics in London will have this as an event, it is always one I look forward to (sorry guys, I know you don’t get it).

The skill, training and athleticism required is incredible. Check out this video of the USA team preparing for London competition.

We hear the word synchronizied used in different ways by our SmartDispenser® customers;

Can the SmartDispenser be used to synchronize other assembly processes in a LEAN manufacturing cell?

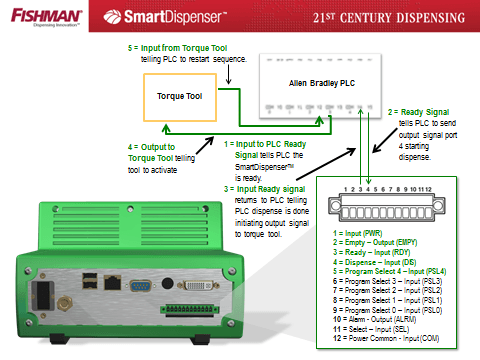

Yes, here is an example using the SmartDispenser® 12 pin I/O terminal connector and Allen Bradley PLC to trigger a torque tool process once the fluid dispense process is completed.

Can the SmartDispenser® internal data collection reports synch up with our MES system? Yes, Manufacturing Execution Systems such Camstar monitor and synchronize manufacturing activities across globally distributed plants and then link them in real-time to the enterprise. End users that utilize computerized, networked manufacturing machinery such as the SmartDispenser® for fluid dispensing, are able to automatically generate dispensing production reports in an Excel .CSV file without human intervention for export to an MES.

How do manufacurers use the SmartDispenser® as part of their their LEAN and synchronized manufacturing initiatives? The SmartDispenser® automatically records key data for value stream analysis so that end users are able to use the LEAN process to remove waste and quickly implement changes. Synchronized manufacturing as part of LEAN is the systematic movement of information, materials and other resources, through all stages in a manufacturing process, in concert with market demand. SmartDispenser® users can utilize the Syringe Reorder program to react just in time to market demands; SmartDispenser® customers simply enable the Inventory Scan App

- Scan bar code on inventory bins generating automatic reorder quantities.

- Visual inspection indicates reorder needed.

- Bar code scanned, Part Number, order quantity and price in shopping cart.

- Click and send an automatic order request from production to buyer or a send direct to Fishman®.