For years fluid dispense systems lacked the ability to deliver high levels of precision and control. That was not a major disadvantage since in the past many applications simply did not require heightened degrees of accuracy and command. But as applications became more sophisticated, the means of assembly had to follow suit. Unfortunately, fluid dispensers relying on old technologies; specifically those using unstable and unpredictable compressed air to dispense fluids, could not keep pace with the elevated assembly needs of more advanced products.

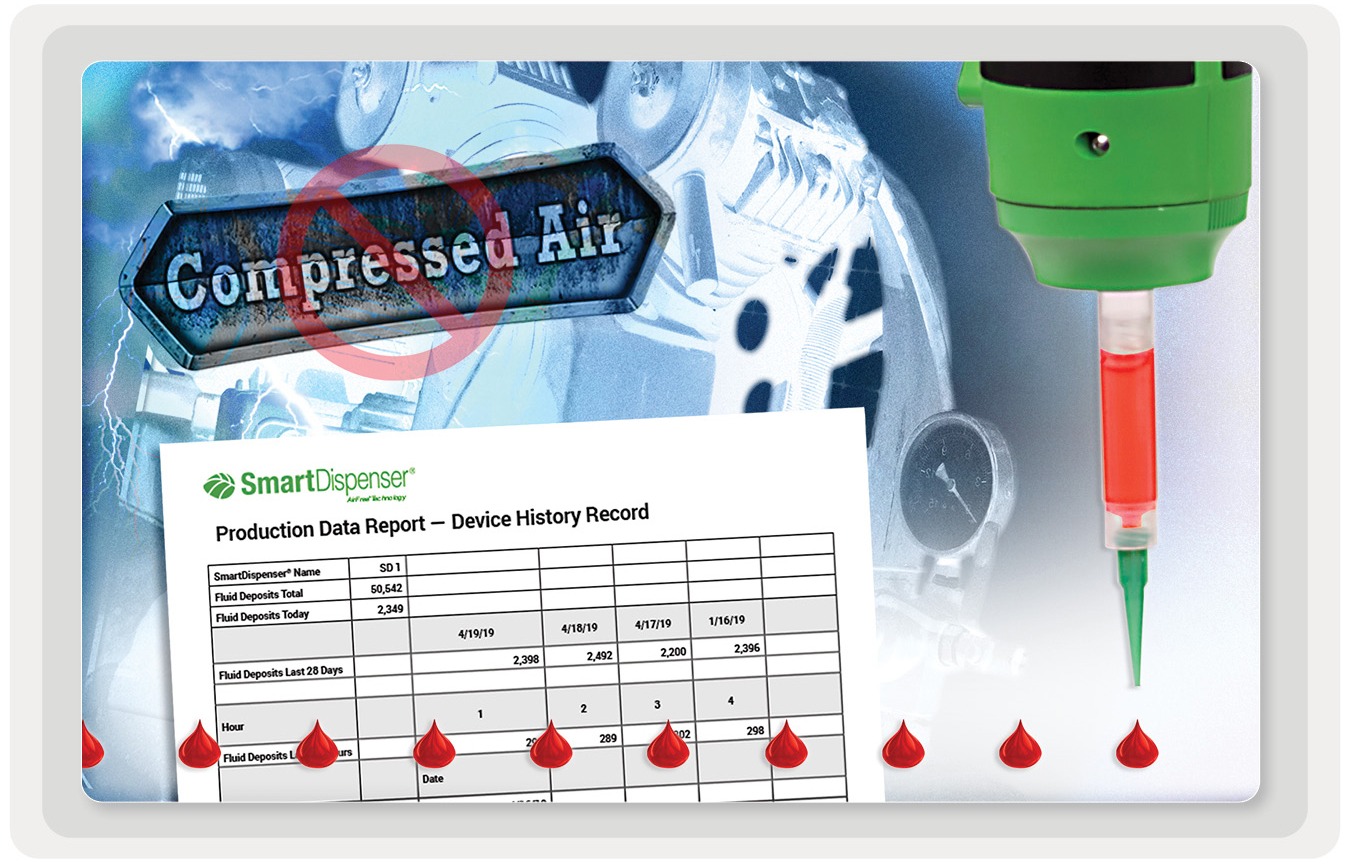

The other vital element after precision and control that manufacturers using air-driven fluid dispense systems are deprived of is the ability to collect and record important production data; information necessary to help operations run more efficiently. The only way manufacturers can get the three missing ingredients for success is to employ a fluid dispense system that is not shackled to compressed air, but instead takes advantage of a solution that dispenses with air and instead turns to algorithms to deliver the winning combination of precision, control and data.

Algorithms deliver the precision and control needed today

Fishman® Corporation is the first and only company that enables manufacturers to achieve optimum precision and control in fluid dispensing because it gives them the ability to apply algorithms to a mechanical drive. This allows for the delivery of fluid deposits with the highest degree of repeatability, and makes adjustments simple because parameters such as fluid deposit size, speed, and reverse motion are fool-proof numerical inputs instead of hit-or-miss calculations. This mitigates the impact of an

epoxy’s changing viscosity on the fluid deposit volume, making workstation-to-workstation performance standardization possible.

AirFree® Technology also delivers the third component for success: data

AirFree® Technology is a patented platform on which manufacturers can add any number of smart features to help increase productivity, eliminate human error and enhance security. But when the SmartDispenser® is delivered to manufacturers it is already equipped with innovative features that give it the capacity to collect and record the important data that populates the SmartDispenser®’s SQL database. One of the smart capabilities built into every SmartDispenser® is a feature that lets it record the device’s history. This allows manufacturers to automatically collect and record much of the valuable production data created during each workday, which can be put into reports that can be accessed by and emailed to all those who need it to make important decisions

Data: the gift that keeps on giving

The production data that goes into these reports can be used for workstation-to-workstation performance reviews and for cost accounting at the point of fluid dispense. Plus, should a quality rejection occur, the data can provide critical information to help production managers diagnose what went wrong with each workstation, as well as give management a clearer picture of what is happening on the assembly line. All this makes it easier for stakeholders up and down the line to take quick and appropriate action.

All this is laid out in far greater detail in a special White Paper published by Fishman® Corporation: To Ensure Greater Profitability, Manufacturers Need Fluid Dispensers that Deliver Precision, Control and Data. Click here to download your copy. We are confident that you will find the information therein to be of great value to you

All this is laid out in far greater detail in a special White Paper published by Fishman® Corporation: To Ensure Greater Profitability, Manufacturers Need Fluid Dispensers that Deliver Precision, Control and Data. Click here to download your copy. We are confident that you will find the information therein to be of great value to you