Syringe Filling System

Syringe Filling System

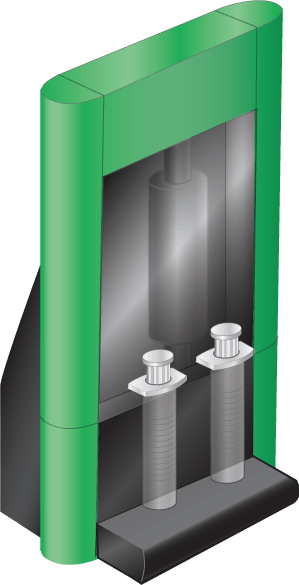

The SmartDispenser® Syringe Filling System is specifically designed for use with all Fishman® SmartDispenser® products. There are three specific features defining the SmartDispenser® syringe filling machine from other syringe fillers.

The syringe filling station is smart. Fully automated when connected to the SmartDispenser® Priming System the priming system relays the syringe size and dispense volume to the filling station and the filling station uses the information to automatically set the fill height eliminating the need for a production worker to set the fill height.

The syringe filling station is smart. Fully automated when connected to the SmartDispenser® Priming System the priming system relays the syringe size and dispense volume to the filling station and the filling station uses the information to automatically set the fill height eliminating the need for a production worker to set the fill height.- The fill height of each syringe is exactly the same within a fraction of an inch.

- Because the syringes are filled to the same height, when using multiple Push-to-Connect™-Linear Drive Dispense Guns combined with a SmartDispenser® 19″ Din Rail Integration Kit (SDIK) or the SmartDispenser® Benchtop Automation System, all the syringes will empty at the same time allowing for all the dispense guns to be changed at the same time minimizing downtime.

- All the wetted parts are disposable. This eliminates the need for costly cleaning downtime with dangerous cleaning fluids such as Methyl Ethel Ketone (MEK) or Acetone. The SmartDispenser® Filling Station Rebuild Kit provides replacement of all wetted parts. The wetted parts can be changed in minutes by hand. No tools required.

The SmartDispenser® Filling Station uses Fishman® AirFree® technology. A powerful stepper motor displaces fluid from the filling chamber positively displacing fluid into two syringes at a time. The automated syringe filling station is compatible with any 0-100 PSI pressurized tank or cartridge reservoir. The syringes can be filled, capped and stored in a filling rack for later use.

The SmartDispenser® syringe filling system is schedule to release March-April 2012. Fishman® Corporation is taking pre-orders for the system now. Please contact your Fishman® Sales Representative for details.